Are you searching for a reliable cast iron foundry exporting to the USA, one that delivers consistent quality, dependable lead times, and cost-efficient solutions?

Many American manufacturers face challenges such as uneven delivery schedules, limited customization, or high local production costs when sourcing from iron foundries in the USA. AKP Ferrocast bridges this gap by exporting precision-engineered castings from India to customers across the United States through efficient logistics channels and dedicated service support.

According to Grand View Research, the USA cast-iron industry was valued at USD 13.04 billion in 2021 and is projected to reach USD 21.26 billion by 2030. With the nation’s strong dependence on durable components for machinery, automotive, and infrastructure applications, AKP Ferrocast is a trusted export partner supplying cast-iron components to the USA market, combining decades of engineering excellence with modern metallurgical practices.

Casting Expertise Reinforced by Technology

Founded in 1978, AKP Ferrocast has over four decades of experience in metal casting and machining. From our advanced foundry complex in Belagavi, India, we produce ductile iron castings for USA OEMs requiring high strength and fatigue resistance, including clients in the United States.

Our facilities integrate:

- Automated moulding and core-making lines

- In-house pattern development

- Chemical and metallurgical laboratories for microstructure evaluation

- Non-destructive and mechanical testing for each batch

Our integrated process ensures consistent quality and traceability.

AKP Ferrocast functions as one of the most dependable foundries exporting ductile iron castings to the USA, providing turnkey export support, secure packaging, and timely shipments through ports such as Mumbai. Delivery channels include routes to ports such as Houston, Baltimore, and Savannah.

USA Iron Casting Market – Opportunities and Growth

The North American iron-casting market was valued at about USD 17 billion in 2024 and is projected to reach USD 29 billion by 2034, with the United States representing 84 percent of the total share. Growth is driven by:

- Electric-vehicle drivetrain components

- Infrastructure renewal programs

- Rail, construction, and heavy-equipment manufacturing

Gray iron remains cost-competitive and machinable, while ductile iron continues to expand rapidly in rail, structural, and automotive applications.

As the USA economy invests heavily in advanced infrastructure, AKP Ferrocast supports OEMs and Tier-1 suppliers by providing custom iron castings for USA requirements, combining international quality with efficient export economics.

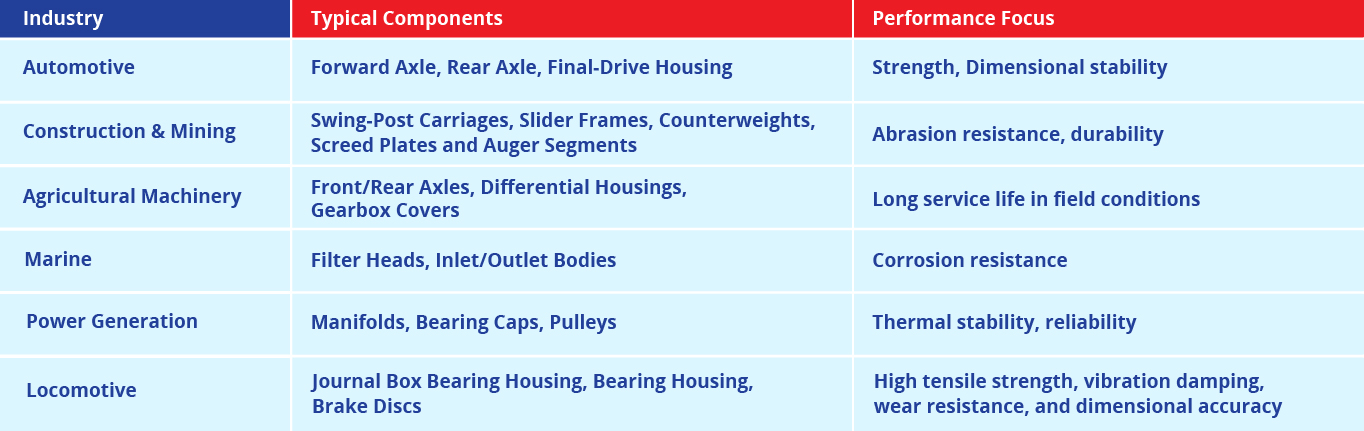

Key Industries We Support with Custom Iron Casting

Our custom iron castings for USA clients are engineered for demanding duty cycles and challenging environments.

We design and export metal cast solutions for the USA that meet high-precision and high-strength expectations across these industrial sectors.

Metal Casting Grades and Materials

As a cast-iron foundry exporting to the USA, we produce multiple grades under international specifications:

- White Cast Iron (ASTM A532) – Exceptional hardness and wear resistance

- Gray Iron (ASTM A48 Class 30–60) – High machinability and vibration damping

- Ductile Iron (ASTM A536 Grade 60-40-18 to 100-70-03) – Superior tensile strength and elongation

This range allows us to address varied metal-casting USA requirements, from light equipment housings to heavy machinery components.

Export and Logistics Process to the USA

Our logistics model is built for consistency, documentation accuracy, and predictable delivery.

- Specification Review – Two-way technical communication with clients to finalize drawings, materials, and tolerances.

- Casting & Production – Manufacturing under controlled process parameters, adhering to ASTM/EN standards.

- Machining & Finishing – CNC machining and surface treatment to deliver ready-to-assemble components.

- Inspection & Testing – Dimensional verification, chemical analysis, and metallurgical certification.

- Packaging & Documentation – ISPM-compliant wooden crates and full export documentation.

- Shipping & Delivery – Dispatch from Indian ports with reliable shipments routed via ports such as Houston, Baltimore, and Savannah, coordinated through USA logistics partners.

This process ensures a traceable and hassle-free supply for American buyers.

Our Manufacturing Locations

We manufacture in India and supply to the United States, offering precision iron castings backed by verified material control, dimensional accuracy, and compliance with global standards such as ASTM A48 and ASTM A536. It has manufacturing facilities located in Karnataka, India, which is close to the Mumbai port (Nhava Sheva) and has air connectivity countrywide as well as internationally. Our foundry in India exports iron castings directly to customers across the United States.

Specialized Iron Casting Offerings for the USA Market

Our metal-casting services for the USA include:

- Gray Iron Casting – Vibration-resistant precision parts

- Ductile Iron Casting – High-strength, fatigue-resistant components

- White Iron Casting – Wear-resistant for abrasive and high-impact applications

- Custom Casting Solutions – Tailor-made castings for OEM applications

- Prototyping and Product Development – Short-run or pilot manufacturing

- Machining and Finishing – CNC-machined surfaces and drilled interfaces

- Testing and Inspection – Spectro analysis, microstructure validation, tensile testing

- Export and Supply Support – End-to-end shipping coordination and documentation

Quality Systems and Core Competencies

AKP Ferrocast delivers castings from 10 kg to 500 kg, supported by 40 CNC machines and an installed capacity of 30,000 metric tons per annum.

We operate in alignment with IATF 16949:2016 standards, ensuring each batch meets metallurgical, dimensional, and mechanical specifications before shipment.

Core strengths include:

- In-house pattern design and tooling

- CAD/CAM-based simulation for defect-free molds

- Shot-blasting and finishing facilities

- Continuous improvement through metallurgical feedback loops

Why USA Industries Trusts AKP Ferrocast?

With decades of experience in ductile and gray iron casting, AKP Ferrocast combines Indian manufacturing scale with export precision for American industries.

Our global clients, such as Volvo, JCB, Caterpillar, Crane, Emerson, and Cummins, appreciate our capability to provide dimensionally consistent parts, which can be incorporated into their supply chains without any problems.

- USA buyers choose AKP Ferrocast for:

- Reliable supply and quality traceability

- Competitive landed cost versus domestic foundries

- Consistent delivery via multiple USA ports

- Compliance with ASTM and customer specifications

Get in Touch

Please get in touch and our expert support team will answer all your questions.

Contact Us

Looking for premium cast iron solutions in the USA?

Have a project that requires custom iron casting for the USA?

AKP Ferrocast offers dependable solutions for gray and ductile iron components, engineered to meet the toughest industrial standards.

Mobile: +91 9448497514 / +91 8147228666

Email: enquiries@akpferrocast.com

Let’s build long-term partnerships grounded in technical accuracy, reliability, and global delivery efficiency.

Frequently Ask Questions

Do you supply custom iron castings to the USA?

Yes. We export Gray, Ductile, and White iron (high chrome) castings according to customer drawings, from prototype to full-scale production.

Do you offer machining or coating after casting?

Yes. Our facilities include CNC machining, drilling, grinding, and surface finishing, providing ready-to-assemble parts.

What advantages do iron castings provide?

They are cost-effective, strong, and vibration-resistant, making them ideal for vehicles, infrastructure, and heavy-equipment applications.