Power Generation Casting

For Large Gensets

Power generation is the backbone of modern society, and it provides energy supply in households, industries, and services. A powerful industrial sector is extremely dependent on materials that can work at optimal conditions under extreme conditions that might include high temperatures, pressure, or a corrosive environment. They should be accurate, corrosion-resistant, and very strong, and in these parameters, a cast part supplier to the power generation business will play a major role. At AKP Ferrocast, we are committed to providing world-class power generation 400 KVA Genset iron-casting solutions that meet the stringent demands of the energy sector.

From steam and gas turbines to auxiliary systems, our products guarantee an uninterrupted operation of power generation 400 KVA genset systems. This blog brings out the different products, processes, and expertise that make us a leader in the industry.

Power Generation Casting Products

Power generation components systems play an important role in making them efficient and reliable. At AKP Ferrocast, we manufacture an extensive range of products for the energy sector. Here’s our list of major products:

Our range of Power Generation casting include the following:

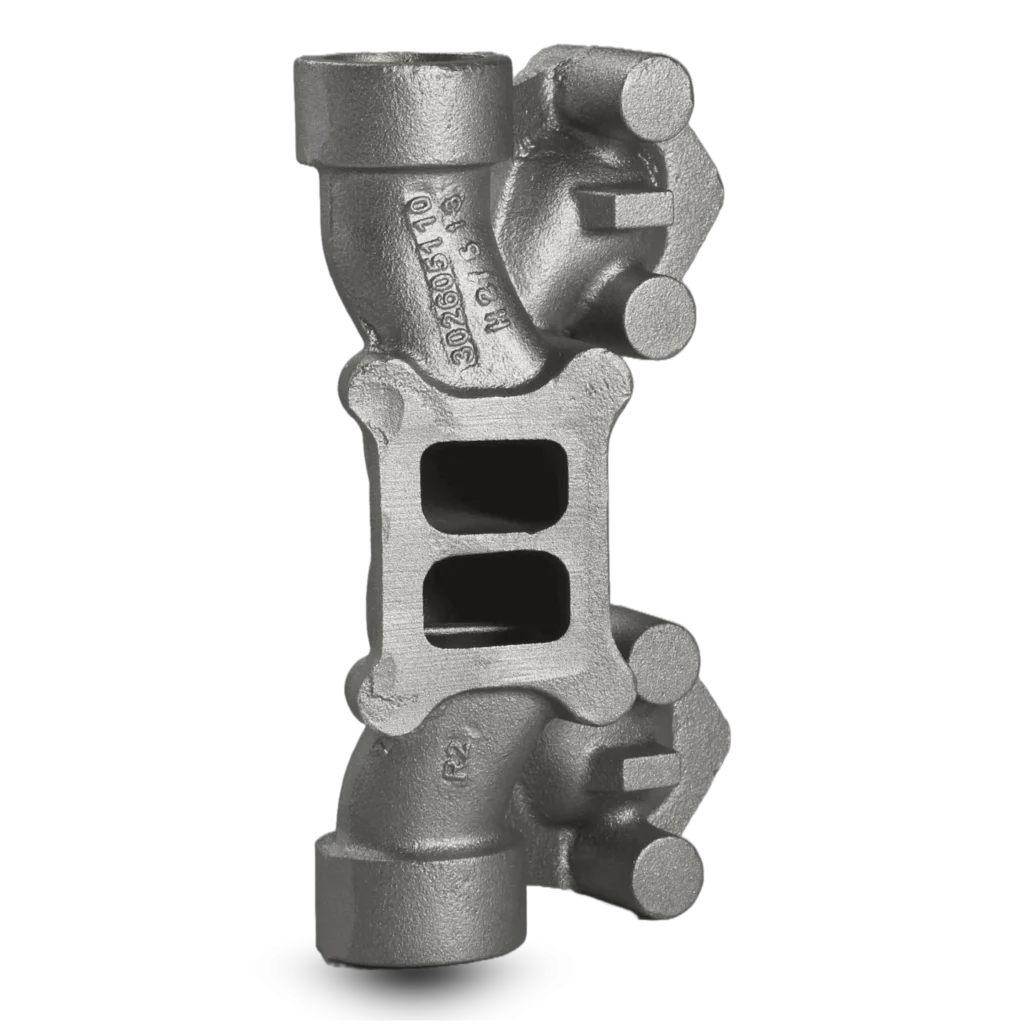

1. Manifolds

A manifold is one of the most important parts in engines and industrial systems that distribute fluids or gases to other parts of a machine. AKP Ferrocast manufactures manifolds with precision and toughness to resist the high pressure and extreme conditions of operation. These manifolds develop power generation systems, which are integral parts of many industrial applications, to be efficient and reliable.

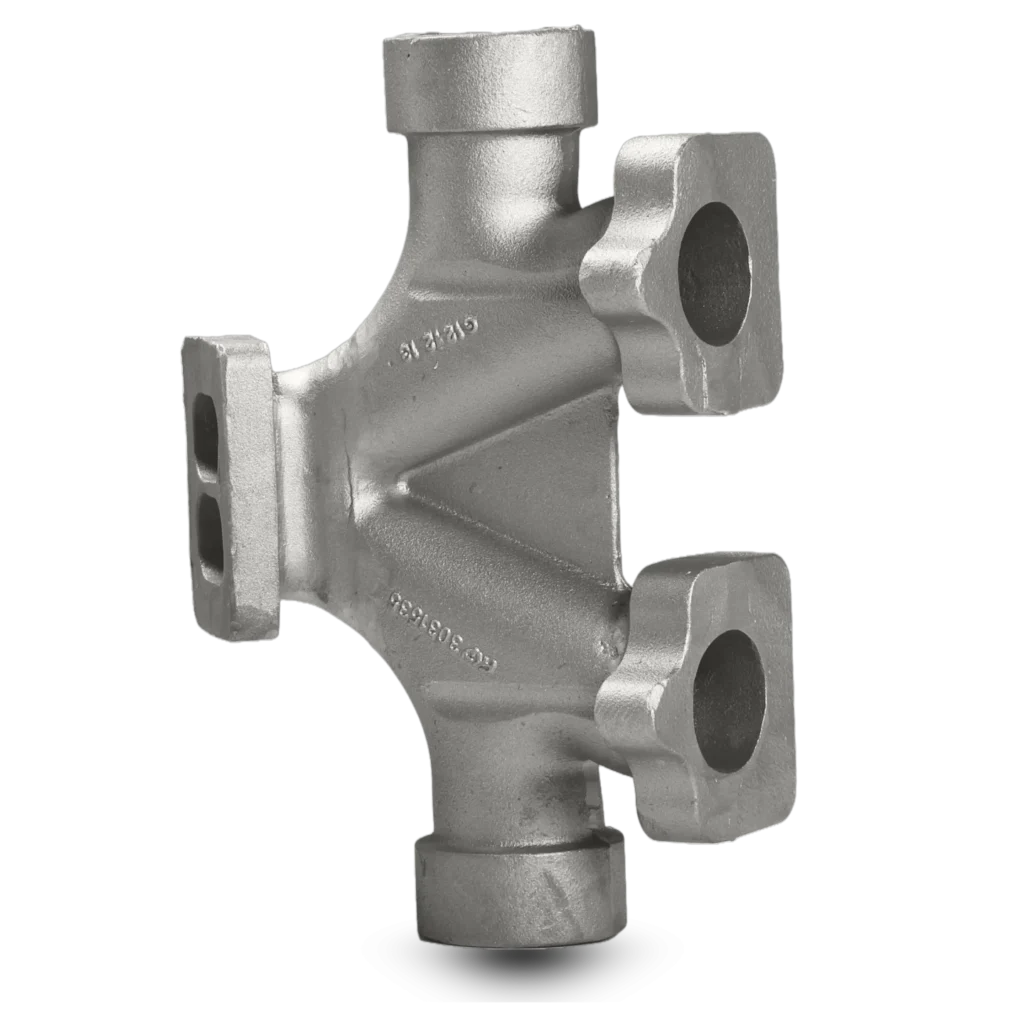

2. Exhaust Manifolds

The central position of the exhaust manifolds is toward leading exhaust gases from cylinders of the engine into the exhaust system. We manufacture high-quality and heat-resistant exhaust manifolds that give assurance of great performance in extreme temperatures. Our exhaust manifolds are made precision-oriented and strong enough to build a less-in-emission and as-efficient engine as possible.

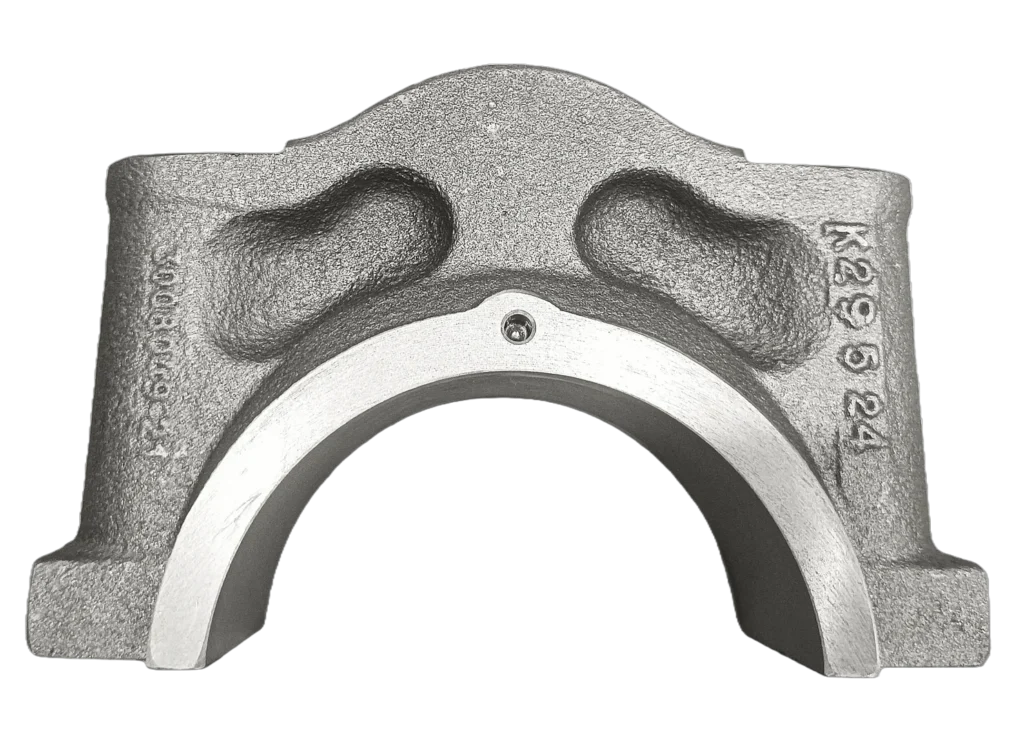

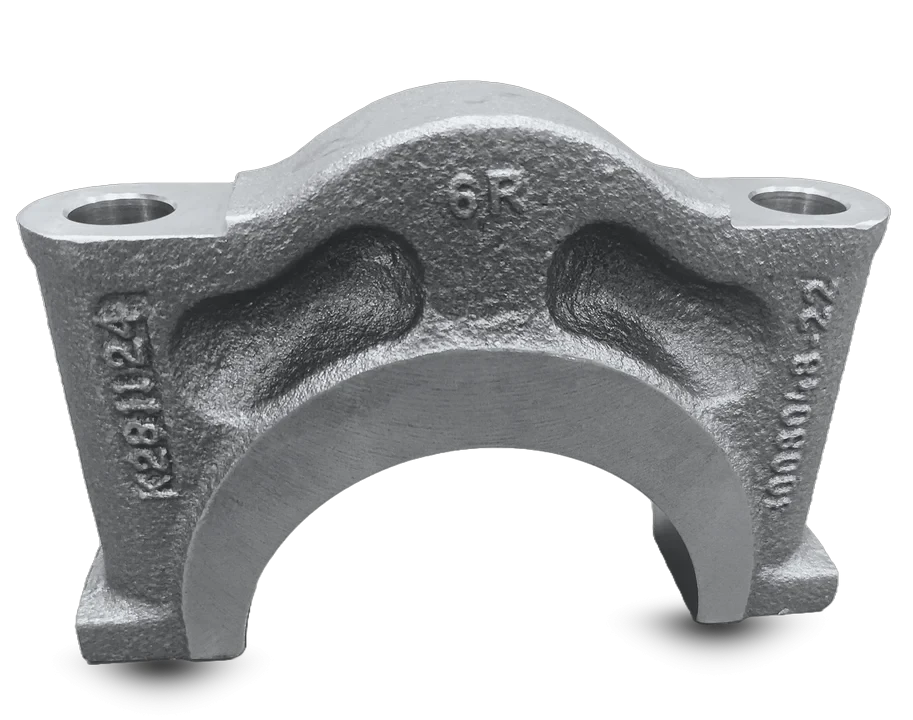

3. Bearing Caps

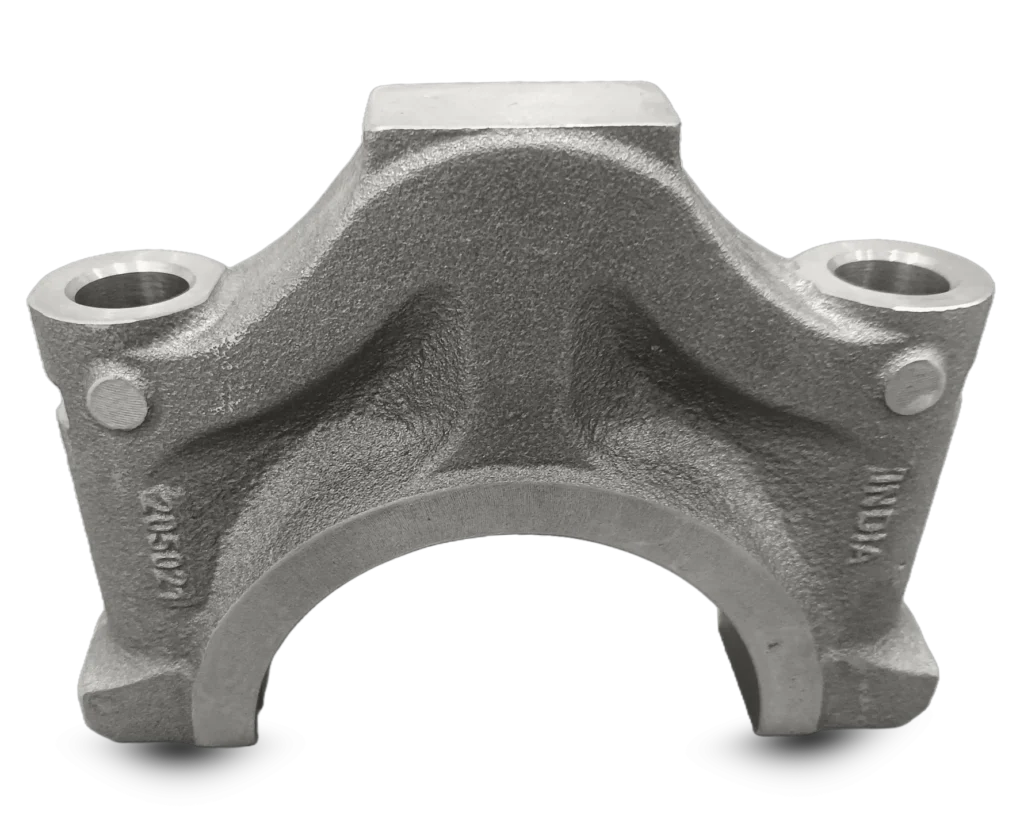

Bearing caps are the protective and supporting parts of bearings. These ensure smooth running while reducing wear on bearings, making them one of the most important parts of machines and engines. We design and manufacture bearing caps made from high-quality materials to provide precise dimensions with good durability. This enhances the systems for power generation, giving the performance even under stress at its best.

4. Pulley

Our pulleys provide smooth efficient running through power transmission systems from the engine and other industrial requirements. Pulleys offered by our company are designed to be less likely to wear out early. We make precision- engineered pulleys to meet high reliability requirements with regard to the longer life-span of equipment catering to both industrial and power generating specifications.

5. Support

Support components are an integral part of stability and structural reinforcement to machinery and equipment. We manufacture supports that bring strength and precision to high-load and vibration conditions. These components ensure long-term reliability and safety of the power generation systems.

6. Connection

Connections are one of the major parts connecting many systems in machines and thus ensure smooth communication among systems. We manufacture quality connection parts with good dimensional accuracy and durability. Such parts are designed to be reliable in demanding environments; hence, they form part of efficient power generation.

7. Brackets

Brackets are of significant significance in supporting and stabilizing apparatuses in industrial and power generation applications. Casting brackets are sturdy and corrosion resistances and thus capable of holding heavy loads and enduring different unfavorable weather conditions. We provide specialized bracket solutions that meet the specific needs of the customer.

Discover Our Power Generation Casting Solutions – Elevate Your Manufacturing Process with AKP Ferrocast's Precision Parts.

Our Commitment

- No Compromise on Quality: We have quality assurance checks on every power generation iron casting, and we ensure that it meets the highest quality standards.

- Innovative Solutioning: We are driven by the latest technologies, such as rapid prototyping and 3D printing, to deliver the most innovative solutions.

- Tailored Products: Since no two projects are alike, we design tailored solutions for the specific needs of our customers.

Our Production Process

- Material Selection: A good casting starts with choosing the right material. We use high-performance alloys that include ductile iron, stainless steel, and Hastelloy for various applications.

- Design Optimization: Our engineers closely interact with our clients to produce castings that are most appropriate, operable, affordable and effective to use.

- Tooling and Casting: The high-tech moulding techniques applied in our production ensure defect-free precise castings. Our facilities are technologically advanced to address complex designs and high production quantity runs.

- Heat Treatment: In order to ensure the strength and performance of the products cast, we treat them using controlled heat treatment techniques.

- Quality Assurance: We rigorously test every casting through hardness testing and dimensional analysis to be within the set standards.

This systematic approach allows every power generation component we make to be of the highest quality possible.

Grades We Use

At AKP Ferrocast, we ensure superior performance and reliability in our power generation components by using high-quality grades of gray and ductile cast iron that meet international standards. Our offerings include EN-GJL-250 and EN-GJS-400-18 as per EN standards, 60-40-18 under ASTM standards, and FG 260 and SG 400/18 as per IS standards. The strength of the grades used will cover their durability, in resistance to demanding power generation industrial conditions. All materials will assure steady quality and a long time, be it iron casting power generation or critical other parts.

Type of Cast Iron (Gray/Ductile)

Gray & Ductile

EN Standards

EN-GJL-250, EN-GJS-400-18

ASTM Standards

60-40-18

IS Standards

FG 260, SG 400/18

Manufacturing Excellence

AKP Ferrocast’s manufacturing excellence is the result of decades of experience and a persistent pursuit of innovation. We deliver casting products of excellent quality while exceeding client expectations through our advanced facilities and skilled workers.

- State-of-the-art Technology: We invest in cutting-edge equipment to ensure accuracy and speed.

- Sustainability: We practice eco-friendly approaches in our operations to minimise our impact on the environment.

- Rapid Turnaround: Our streamlined processes enable us to provide products on time, never at the cost of quality.

We build our reputation on trust, quality, and innovation.

Our Expertise

AKP Ferrocast has over three decades of experience in the power generation casting industry. We specialise in a wide range of applications, from turbines to auxiliary systems. We are highly skilled at handling intricate designs, low and high-volume orders, and customised solutions. Quality and customer satisfaction have always been our focus, which has earned us a trusted position in the global market.

Why Choose AKP Ferrocast for Power Generation Casting

The right casting partner may make a huge difference in the performance and reliability of your power generation systems. Here is why you should choose AKP Ferrocast as the choice of preference:

- Material Expertise: We have an extended range of ferrous and non-ferrous alloys, which ensures they are the perfect match for your application.

- Customised Solutions: Our ability to provide tailored products to specific requirements differentiates us.

- Global Reach: We provide castings to companies worldwide and maintain uniform quality in every order.

- Commitment to Excellence: Quality and innovation are the backbone of our product, which can withstand time.

Whether it is a prototype or mass production, we can deliver excellent results.

Conclusion

At, AKP Ferrocast we pride ourselves on bringing to the world the finest solutions of castings in iron for generating power where durability, accuracy, and reliability are needed. We build products based on decades of experience, high-level technology, and a strong position with quality. Trust AKP Ferrocast for your power generation castings’ every need. Experience unmatched excellence and reliability.

Frequently Ask Questions

What materials are used for manufacturing power generation casting components?

We use diverse high-performance materials to prepare our products. We incorporate ductile iron, stainless steel, and other types of specialised alloys like Ni-Resist and Hastelloy. In choosing these materials, we ensure durability and resistance against extreme situations.

What quality measures do you take regarding your castings?

Quality assurance is in our activities. Every part is tested, from hardness testing to dimensional analysis, and more inspections are made to ensure that the power generation components meet high-quality standards.

Request Pricing Details

Get a comprehensive quote based on your specific needs and requirements. Submit your request to receive detailed pricing, including product specifications, quantities, and delivery terms.