Manifold castings are an essential component in the performance of engines. It directs air into the engine and exhaust gas out of it for efficient operations. Being such an integral part of vehicles as well as various industrial machines, manifold casting is consumed consistently within various industries. A manifold manufacturer provides these vital products that meet the requirements of respective industries on matters related to durability and performance. A reliable manifold supplier provides intake and exhaust manifolds to keep your engine running efficiently and for a long period.

Manifolds are the critical connectors between the different parts of the engine. The manifolds control the emission and drawing of air and gases to and from the engine. These parts are often made from high-strength metals to be able to handle the extremely hot conditions under which the engine operates. Manifold casting equipment manufacturers need to have deep insights into both manufacturing methods and raw materials to offer quality products. AKP Ferrocast is one of the major producers of intake manifold, exhaust manifold, and many other key engine components for various industries.

Manifold Casting Products and Components

AKP Ferrocast provides several manifold casting products designed to cater to the different needs of various industries, such as automotive, heavy machinery, and construction. Each of these products is manufactured with perfection in the most advanced technology and finest raw materials:

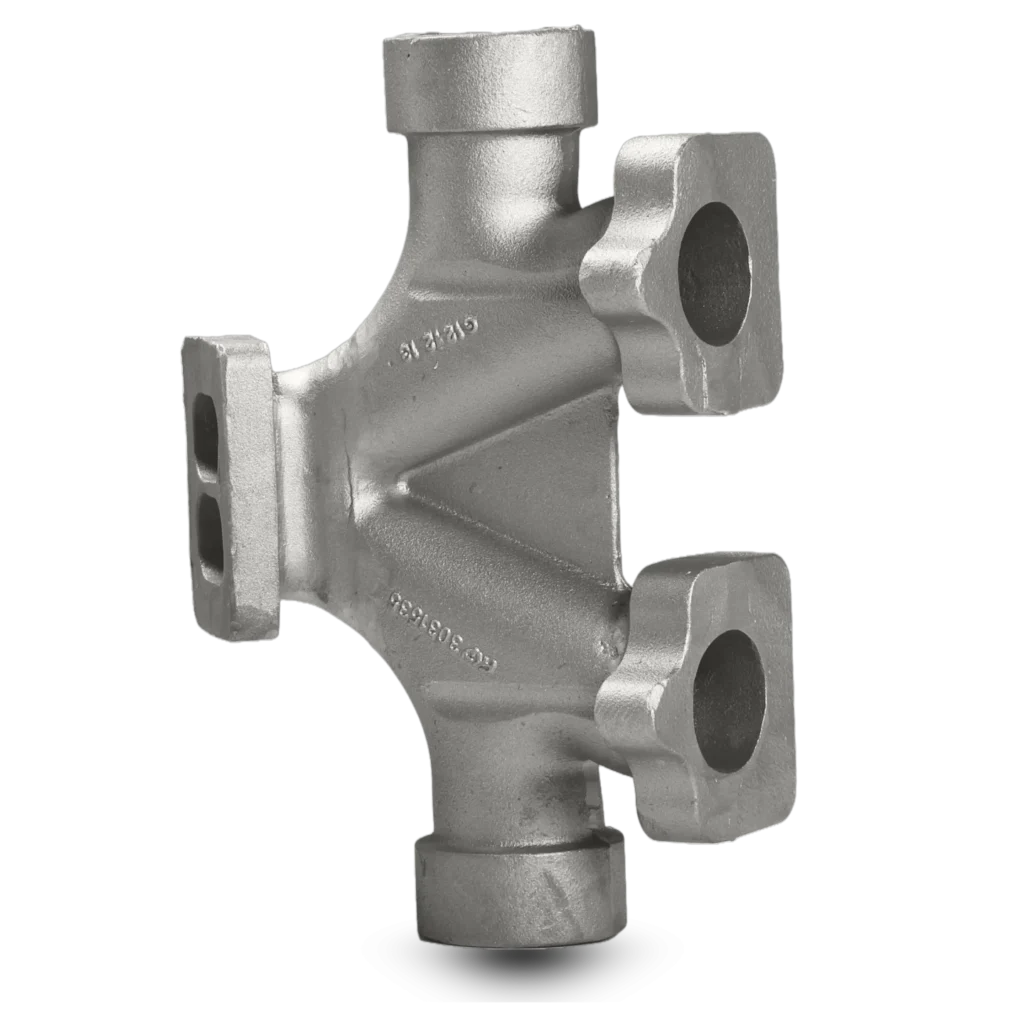

- Intake Manifold: They draw air and distribute it evenly to each one of the cylinders in the engine; in fact, intake manifolds are one of the most important performance systems of an engine.

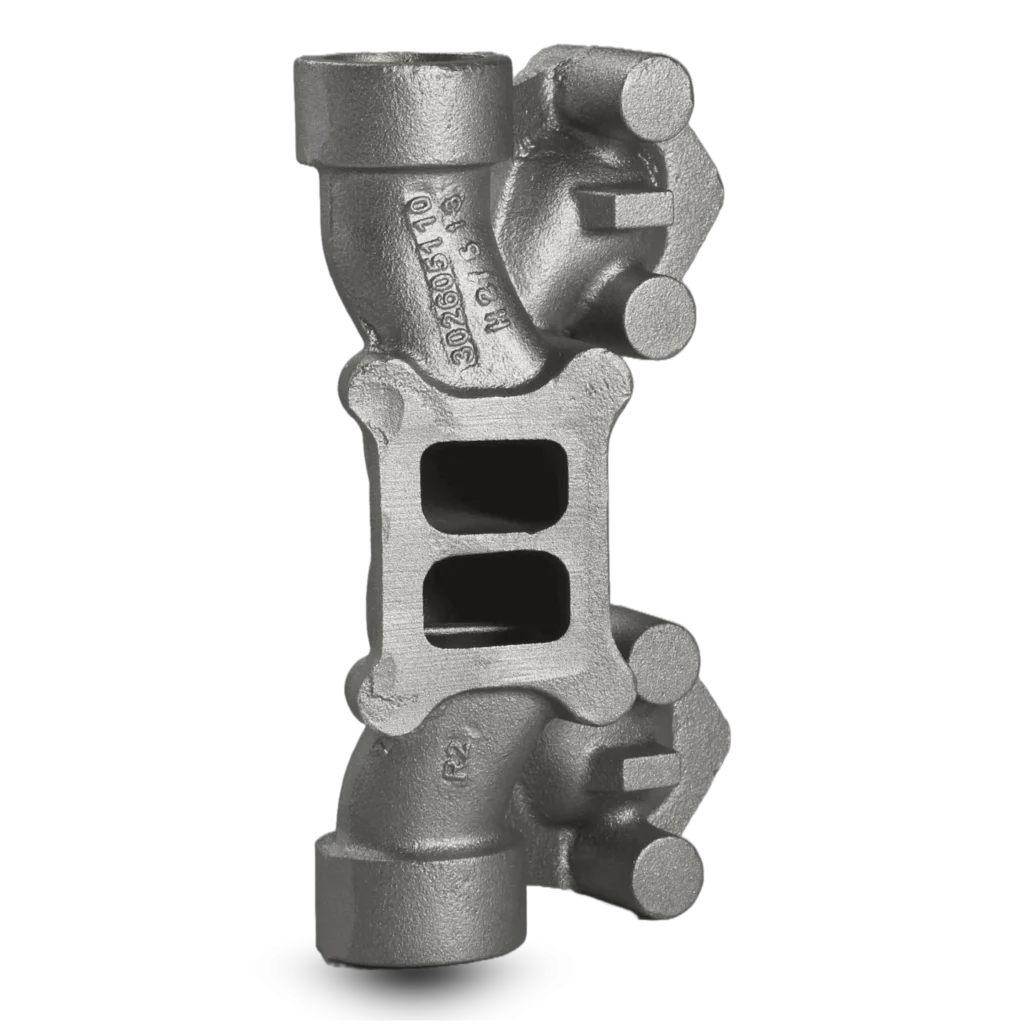

- Exhaust Manifold: They collect the exhaust gases from the cylinder of the engine, directing them into the exhaust pipe while making sure that this process runs smoothly for effective emissions control.

- Turbo Manifold: Our turbo manifolds can handle turbocharged engines with extreme temperatures and are engineered to be tough and durable.

- Water-cooled Exhaust Manifold: These manifolds are required in marine applications for controlling the temperature of an engine along with its exhaust gases direction.

Each one of these manifold parts has been crafted with great care in order to ensure high performance along with a longer operational time even in harsh working conditions.

Intake Manifold Casting

The intake manifold is one of the critical parts of an air intake in internal combustion engines. It provides relatively balanced flow for the air-fuel mixture to all the cylinders so that the engine would run reasonably efficiently. The concept and material used in the manufacture of intake manifolds have a significant effect on the performance of the engine.

AKP Ferrocast excelled in taking intake manifold casting with high strength materials such as aluminum and cast iron. The reason behind their usage lies in their toughness and enormous ability to bear high temperature and pressure. They ensure that the engine moves smoothly in any tough condition.

Exhaust Manifold Casting

The exhaust manifold has a vital role, as it allows exhaust gases from the engine’s cylinders to pass into the exhaust pipe. Material and manufacturing processes are carefully selected for casting exhaust manifold components since they have to withstand high temperatures and resist corrosion.

AKP Ferrocast casts exhaust manifold parts using modern metals, including ductile iron and cast aluminium. These metals ensure the exhaust system of your engine works effectively for quite a long time as they are durable and resistant to corrosion and heat.

Metals & Grades That We Use for Casting Manifold Parts

The type of metal has significant influences on the quality and performance of manifold casting. We at AKP Ferrocast use a wide range of metals based on the client’s specific requirements. Of the widely used metals, some are as follows:

- Ductile Iron: It has excellent strength and toughness properties, which makes it the best choice for casting exhaust manifolds.

- Gray Cast Iron: Gray Cast Iron are used for intake manifold casting primarily because of their high damping capacity and thermal conductivity. They are excellent for high-temperature applications.

- Often used for intake manifold casting, grey iron offers excellent damping capacity and thermal conductivity, making it ideal for high-temperature applications.

- Aluminium Alloys: Aluminum is used for both intake and exhaust manifold casting. It is very light and does not corrode, making it useful for high-performance automotive products.

Our Commitment

AKP Ferrocast provides manifold casting equipment manufacturers with high-quality service to our customers. Our adherence to quality is reflected in our stringent testing and inspection processes. We ensure every manifold casting meets the required industrial standards required. We utilise innovative technologies and materials that improve the performance and reliability of our products.

Production Process

In manifold casting production, there are several critical stages to ensure precision and durability. The general process follows:

- Design and Mold Preparation: Custom moulds are prepared according to the manifold part specifications to be cast.

- Metal Melting: Metals, including ductile iron or aluminium, are heated in a furnace to reach the melting point.

- Casting: Molten metal is poured into the prepared mould, which will take the shape of the manifold.

- Cooling and Solidification: It cools and solidifies to a hard, strong casting.

- Finishing and Inspection: After cooling, the cast manifold is taken out from the mould, cleaned, and then inspected for defects or irregularities.

AKP Ferrocast follows this process for engine manifold products that meet only high-quality standards.

Discover Our Intake and Exhaust Manifold Casting Solutions – Elevate Your Manufacturing Process with AKP Ferrocast's Precision Parts.

Our Expertise

AKP Ferrocast is one of the leading manifold manufacturers with years of experience in creating high-performing, reliable and durable manifold parts. We serve a wide range of industries and different spheres, from heavy machinery and automotive sectors. We are successfully meeting the growing demands of our clients for intakes and exhaust manifolds.

Why Choose AKP Ferrocast Manifolds Casting?

Choosing AKP Ferrocast Manifolds Casting as a casting supplier ensures you have chosen a committed firm with outstanding quality. This is why we stand apart from the rest:

- Global Reach: We produce manifold parts for industries around the globe to meet casting needs.

- Advanced Techniques: We use state-of-the-art technology and processes to create the finest manifold castings.

- Custom Solutions: We offer OEM-specific custom manifold casting services, ensuring that each product meets the needs of our clients.

- Sustainability: With our processes, we try to minimise waste while trying to increase the sustainability of the given system.

Conclusion: AKP Ferrocast- Global Leaders in Ductile Iron and Gray Iron Manifold Casting

AKP Ferrocast commitment to excellence, innovation, and unwavering dedication to customer satisfaction is what makes us stand out in the competitive manifold casting market. Whether it’s intake or exhaust manifold castings, our reliable and high-quality castings products meet the client’s specifications.

Frequently Ask Questions

Do AKP Ferrocast provide custom manifold casting for OEMs?

Yes, AKP Ferrocast does customised manifold casting for Original Equipment Manufacturers. We work closely with our customers to ensure that the final product meets their specific requirements.

What are the different industries that we cast manifolds for?

We cast manifold casting for a variety of industries. These include the automotive industry, marine industry, construction industry, and heavy machinery.

What type of metals can be used to cast manifolds?

We cast manifolds in a wide range of metals, such as ductile iron, gray cast iron, and aluminium alloys, depending on the application requirements.

Request Pricing Details

Get a comprehensive quote based on your specific needs and requirements. Submit your request to receive detailed pricing, including product specifications, quantities, and delivery terms.