What is White Cast Iron? Properties, Advantages, and Applications

White cast iron is a veritably hard and strong type of cast iron. Unlike other types, its carbon is set up in the form of iron carbide ( Fe ₃ C) rather of graphite. When

Hear it from the our experts. Find relevant information from client stories to product information.

White cast iron is a veritably hard and strong type of cast iron. Unlike other types, its carbon is set up in the form of iron carbide ( Fe ₃ C) rather of graphite. When

Metal casting is one of the oldest and most versatile manufacturing processes and is commonly used to create everything from automotive parts to industrial machinery. But the reality is, not all types of metal castings

Carburizing is one of the most extensively used heat treatment processes for perfecting the performance of cast iron parts. In simple terms, the carburizing process involves perfecting the face sub caste of cast iron with

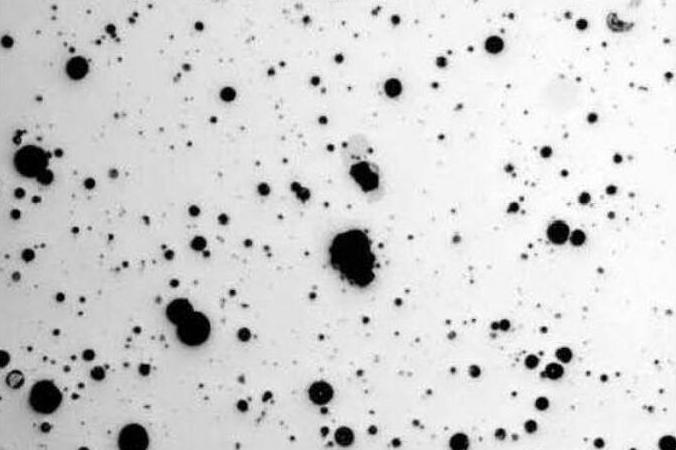

In the world of metal castings, maintaining quality of the product is a non-negotiable priority. Radiographic testing (RT) , a non-destructive test using radiography, has therefore become essential. It enables manufacturers to radiographically screen castings,

Porosity is a common issue in casting that can lower the strength and reliability of metal parts. Even small pores may lead to cracks, leaks, or reduced performance over time. Reducing porosity is important to

In the world of metal casting, quality control is not only important – but this is also necessary. Foundries should ensure that their cast components are free from cracks, porosity, and other hidden defects, which

The Green Sand-Casting Metal Casting Industry is one of the most traditional ways to be widely used yet. Despite being around for centuries, this technique is popular due to its cost-efficiency, flexibility and suitability for

The microstructure of cast iron is one of the most important factors that determine the mechanical properties, performance and purpose of the material for a wide range of applications. From motor vehicle parts to industrial

When talking about the physical properties of the material, it is one of the most important things to consider density. But what is really density? It simply means how much mass is in a material

Shrinkage in metal casting is one of the major phenomena affecting the integrity and quality of cast components. This phenomenon refers to the natural contraction of metals during solidification and results in dimensional and structural

Some of the most salient materials used in several industries are cast iron, which offers sound strength, durability, and excellent wear resistance qualities. Yet, metal properties can be further upgraded and modified to meet the

Metals serve as the backbone of various industries- from automotive to construction and even to aerospace and mining. It is very necessary for the metals to be judged in terms of their quality and performance.

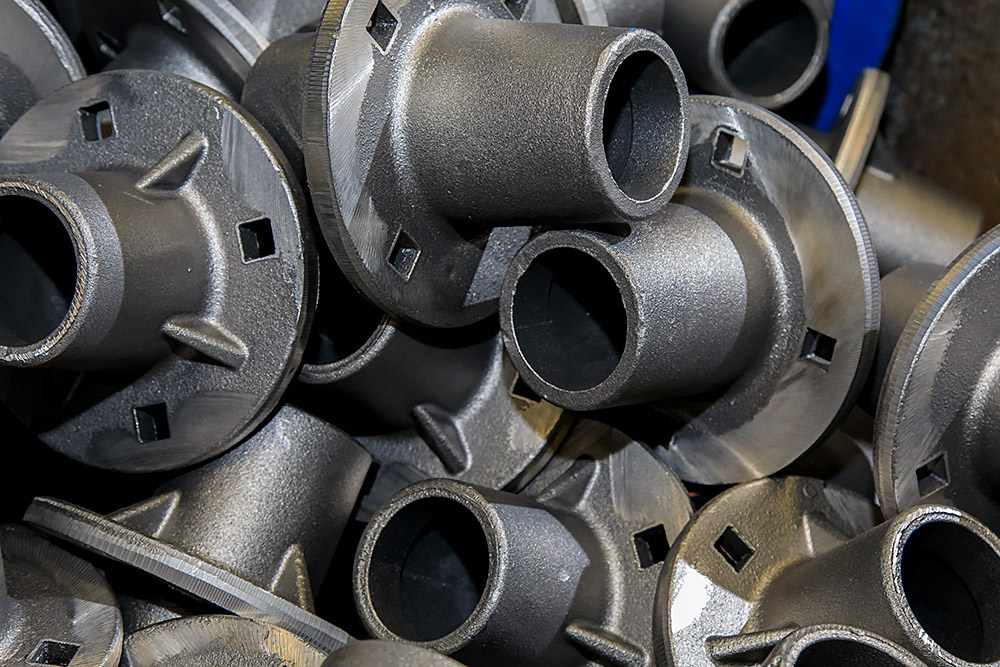

What is CI Casting and How Does it Work? CI casting foundry has been a core process of manufacturing for hundreds of years, allowing industries to manufacture complex metal parts with precision, consistency, and effectiveness.

SG Iron Casting: What it is, Its Advantages and Applications SG Iron Casting, or Spheroidal Graphite Cast Iron or Ductile Iron, is a high-performance engineering material that has transformed different industries with its exceptional mechanical

How the Melting Temperature of Cast Iron Affects the Casting Process? The melting point of cast iron is a crucial factor in the casting process, directly influencing fluidity, solidification, and final product quality. Understanding how

Safety Tips for Iron Casting: What Every Foundry Worker Should Know Iron casting is a very important process in the majority of industries, ranging from automobile to building construction. Yet, working in a foundry is

Top 5 Industries That Rely on Iron Castings Iron Castings have been significant components of industrial development for centuries. They are durable, strong, and inexpensive. They have proved invaluable in a plethora of industries. Iron

What is a Superalloy: Its Manufacture & Uses Superalloys are the unbeknown heroes of contemporary engineering, facilitating advances in some of the most severe industries. Such high-performance metallic alloys have high resistance to temperatures that

What is Malleable Cast Iron? Malleable cast iron serves as an exceptional cast iron form which presents exceptional strength together with flexibility and durability features. The heat treatment of standard cast iron results in malleable

Cast Aluminium vs Cast Iron: What You Need to Know In manufacturing, debates between materials seem to focus mostly on casting cast aluminium vs cast iron. Even though they both get cast almost similarly, both

Casting Defects: Detecting and How to Fix? Casting is one of the most important manufacturing processes in which molten metal is poured into a mold to create components with specific shapes and sizes. One of

How Nodular Cast Iron is Prepared: Step to Step Guide The discovery of nodular cast iron has been nothing short of revolutionary in the production and application of cast materials. These have always offered the

What is Sand Casting and How Does it Work? Sand casting is also one of the oldest and most widely used methods in manufacturing industries for producing metal components. In this sand casting process, molten

Difference Between Ductile Iron and Cast Iron There are several options to consider when selecting iron alloys for any kind of application. One of the most popular options in this regard includes ductile iron and

What is Alloy Casting and Why Is It Useful? Alloy casting is a versatile and generally applied manufacturing process in modern industries that has made it possible for modern industries to manufacture components possessing more

Ferrous Casting vs Non-Ferrous Casting: Differences! Comparison of cast iron vs forged iron reveals some major differences, such as how they are made, their strength, applications, and suitability in any industry. Both forged and cast

Shell Mould Casting: Its Overview and Process Comparison of cast iron vs forged iron reveals some major differences, such as how they are made, their strength, applications, and suitability in any industry. Both forged and

The Difference Between Forged and Cast Iron Comparison of cast iron vs forged iron reveals some major differences, such as how they are made, their strength, applications, and suitability in any industry. Both forged and

What is a Foundry ? A Complete Guide A foundry is a facility for melting and casting of metals in the desired form and shape of a specific product. Metal casting is the backbone of

Introduction to Ductile Iron: Composition and Applications Ductile iron or SG iron is the commercial name for cast iron that possesses great strength, toughness and hardness. Nodular graphite structures are completely met by ductile iron,

Cast Iron vs Cast Steel: Key Differences and Applications Selecting between cast iron vs cast steel when sourcing materials for manufacture, construction, or engineering is important. The variety of properties both metals portray makes them

Gray Iron Casting: Advantages and its Industrial Use Grey iron, or iron casting as it is commonly referred to, has been used in manufacturing for years due to its flexibility and versatility. The term gray

Metal Casting: What It Is, Its Process, and Design Metal casting is a very old but very basic and important industry that involves the use of molten metals for the creation of the required form

Understanding Cast Iron: Its Properties, History and Uses The tale of cast iron dates back to the origins of human civilization. Cast iron boasts a rich history with tales of weaponry and amazing artistry involving