What is Malleable Cast Iron?

Malleable cast iron serves as an exceptional cast iron form which presents exceptional strength together with flexibility and durability features. The heat treatment of standard cast iron results in malleable cast iron which becomes stronger than brittle standard cast iron. Through its heat treatment malleable cast iron becomes stronger and shows better resistance to bending before breaking apart. The material works well across different industrial requirements that demand strong durability and flexible performance. Multiple industrial sectors employ malleable cast iron products for their critical applications because malleable cast iron uses are essential for automotive parts and machinery components along with pipe fittings and agricultural tools.

Table of Contents

Understanding Malleable Cast Iron

The production of malleable cast iron starts with white cast iron heat treatment which creates modifications in the internal structure that increase material properties. The heat treatment procedure converts brittle carbide content into temper carbon which creates a tougher and pliable material. The manufacturing process creates a metal product with cast iron ease of molding and strengthened durability and shock resistance properties for demanding engineering usages. Throughout this transformation process the grain structure achieves refinement which creates better fatigue resistance essential for components that experience multiple stress cycles over prolonged use.

Key Characteristics of Malleable Cast Iron Include

Due to its specific properties malleable cast iron becomes an excellent solution for demanding industrial manufacturing processes. The main malleable cast iron properties:

- High Strength and Toughness: The mechanical strength exceeds that of gray cast iron through its ability to provide outstanding durability under demanding load conditions.

- Good Ductility and Flexibility: The material demonstrates excellent ductility together with flexibility because it resists breaking when forces are applied during impact or bending motions.

- Wear and Corrosion Resistance: The durability of malleable cast iron remains strong against wear and corrosion which creates suitable conditions for moving components exposed to harsh environments.

- Excellent Machinability: Manufacturers can achieve precise manufacturing of complex components with tight tolerances since this material offers excellent machinability properties.

- Good Heat Resistance: High temperature environments do not affect this material which allows it to work in engines and furnaces and other heat-intensive systems.

- Shock Absorption Properties: The material stands out through its shock absorption properties which enable uses of malleable cast iron as parts of automotive and industrial machinery.

Benefits of Using Malleable Cast Iron

Manufacturers prefer malleable cast iron because of its several advantageous properties for industrial usage. Several beneficial characteristics stand out for this material including:

- Versatility: The material shows excellent versatility because it serves numerous industries which include railway development and aerospace production together with automotive manufacturing applications and construction applications.

- Cost-Effectiveness: This material demonstrates cost effectiveness when combined with its high strength properties since it remains budget-friendly compared to various steel alloys.

- Long Lifespan: Besides its long durability it helps parts survive wear and corrosion which results in longer-lasting components that decrease maintenance requirements and alleviate replacement expenses.

- Structural Integrity: Structural Integrity enables the material to sustain its shape together with its strength even operating under heavy loads combined with extreme conditions.

- Environmental Sustainability: The production methods enable metal recycling and material repurposing since this defines it as an environmentally sustainable option.

- Impact Resistance: Impact Resistance enables the material to absorb mechanical shocks which benefits both suspension systems in automobiles and mechanical linkages.

Limitations of Malleable Cast Iron

While having many positive characteristics, Malleable cast iron also comes with restrictive technical factors that need proper evaluation.

- Production Complexity: The manufacturing costs escalate because heat treatment requires special equipment coupled with expert personnel to complete the process.

- Limited Size Capability: There exists a manufacturing restriction on component scale because shrinkage effects alongside material property changes limit its use to small to medium part dimensions.

- Lower Tensile Strength Than Some Steels: Its tensile strength levels fall below specific steel alloys which prevents use in applications demanding maximum strength.

- Susceptibility to Oxidation: The material shows better corrosion resistance compared to several metals but extended contact with tough conditions results in surface damage unless the product receives appropriate protective measures.

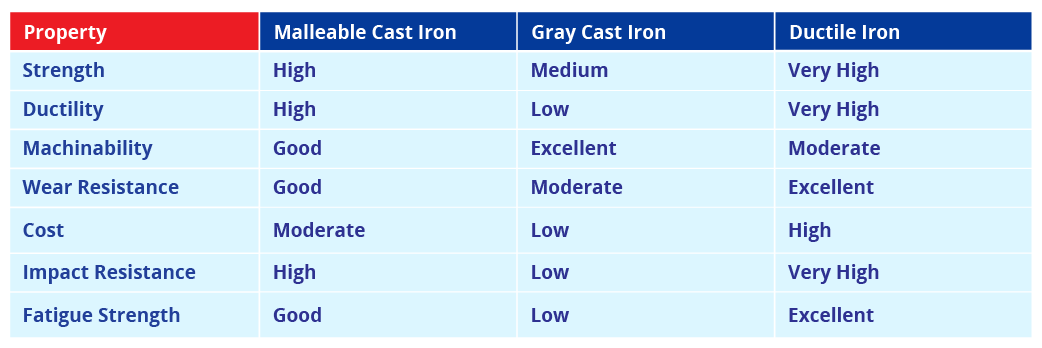

Comparing Malleable Cast Iron with Other Cast Iron Types

Detailed comparisons exist between malleable cast iron and gray cast iron and ductile iron types of cast iron material. Here’s how they differ:

Production Process of Malleable Cast Iron

Special factory procedures serve to create the special qualities that malleable cast iron requires. The key steps include:

- Casting White Iron: Manufacturers begin by creating products from white iron that contains high amounts of carbon and displays brittle characteristics because of its hard structure.

- Annealing Process: The components of cast production receive extended time under controlled high-temperature heat treatment ranging from 850 to 950 degrees Celsius.

- Carbon Transformation: White iron transforms its carbon material into temper carbon during the process which creates ductility in the material along with improved mechanical characteristics.

- Cooling and Machining: The casted components receive slowing controlled cooling followed by final component machining after annealing.

- Quality Control and Testing: The implementation of advanced inspection methods guarantees uniformity concerning the materials’ structure together with strength attributes and mechanical performance which results in high-quality standards.

Advancements in Malleable Cast Iron Technology

Modern technological innovations have increased the effectiveness and reliability of malleable cast iron manufacturing processes. Some recent innovations include:

- Enhanced Alloying Techniques: By adding nickel combined with molybdenum and copper to the alloy structure engineers achieve greater strength levels while improving heat resistance and corrosion resistance properties.

- Better Heat Treatment Methods: The customized annealing methods lead to improved ductility because they minimize production expenses while maintaining superior performance.

- Precision Casting Methods: 3D printing technologies integrated with precision casting provide better dimensional accuracy and decrease cast-related waste and enhance customized cast results.

- Environmental Improvements: Both energy-efficient annealing techniques and waste reduction projects act as environmentally sustainable production methods which facilitate the goal of minimizing environmental impact.

- Smart Quality Control: Artificial intelligence-based monitoring platforms incorporated into production systems provide both reliability for product specifications and automated defect recognition early during manufacturing runs.

Conclusion

The industries use malleable cast iron as one of their primary materials because of its durable nature along with versatility malleable cast iron benefits. The material offers an excellent combination of strength and flexibility together with manufacturing potential that benefits malleable cast iron applications needing impact protection and lasting durability performance. Construction complexity and size restrictions represent main obstacles during production. The future of industry depends on malleable cast iron as an exceptional material for crucial applications because it provides both high performance and economical value. The production of premium-grade ductile and gray cast iron castings by AKP Ferrocast helps global markets to obtain high-quality solutions that match current engineering requirements.

Frequently Ask Questions

What is called Malleable Cast Iron?

The heat treatment process which refines microstructure helps malleable cast iron obtain its name by enabling flexibly shaped deformations under stress without breaking.

Can malleable cast iron be welded?

Cast iron material in its malleable state can be welded under specific preheating and post-welding heat treatment conditions. Specialized preheating procedures together with post-weld heat treatments are necessary for welding malleable cast iron therefore welding this material remains a complex process.

What are the main elements in malleable cast iron?

Malleable cast iron consists mainly of four elements. The main components of malleable cast iron are iron with carbon alongside silicon, manganese, sulfur, phosphorus and other alloying elements that improve its properties.

What are the main elements in malleable cast iron?

Malleable cast iron shows what distinctions stand regarding its properties when compared to ductile iron. Each material exists on a different strength scale since ductile iron delivers better flexibility along with higher tensile strength and malleable cast iron excels at machine operations along with superior resistance against impact and fatigue.