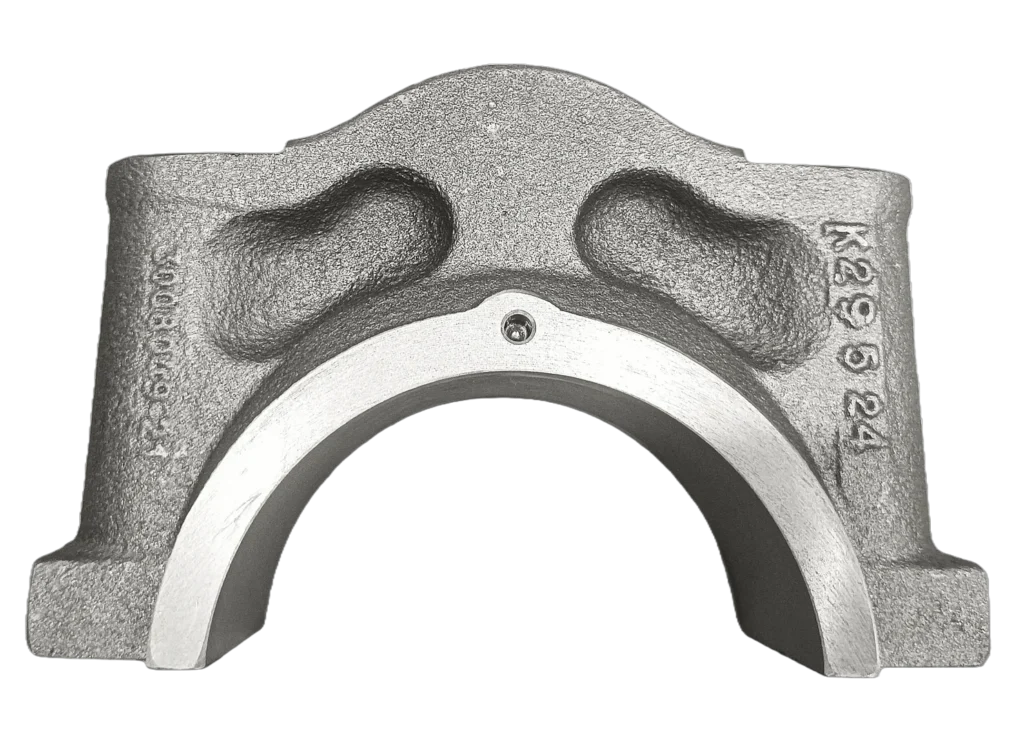

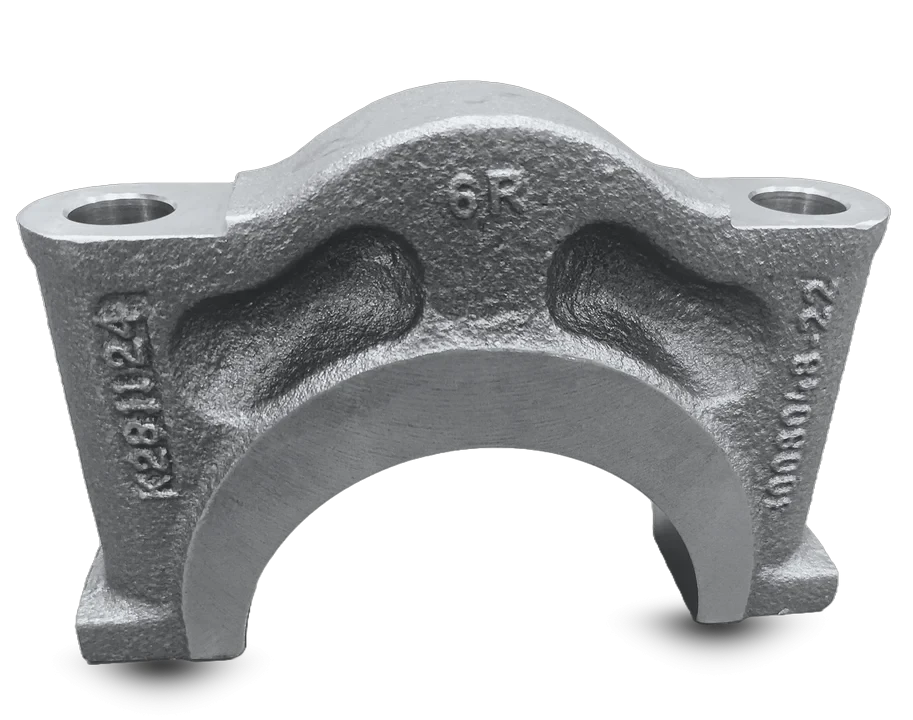

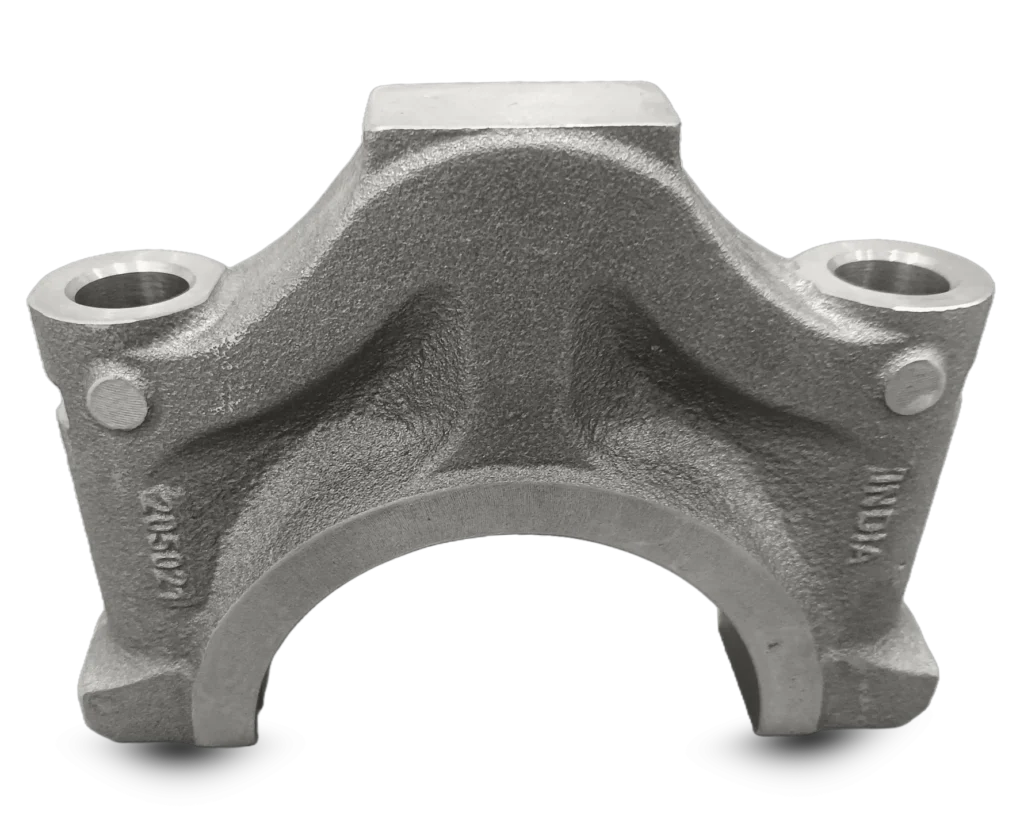

Bearing Caps Iron

Casting Suppliers

Bearing caps are the critical parts in all machines used for bearing support and mounting of bearings, which ensure accurate alignment of the bearings and distribution of loads. AKP Ferrocast uses cast iron to make bearing caps with high durability and wear resistance. Bearing caps constitute a significant application in areas ranging from automotive to heavy machinery. Our bearing cap iron casting ensures smooth running while reducing vibration when operating. AKP Ferrocast is one of the major worldwide bearing cap casting manufacturers offering high-quality cast iron bearing caps to fulfill the growing worldwide demand of various industries.

Types of Cast Iron Bearing Caps Products

Bearing Caps come in several forms, all of which are constructed to meet specific needs in relation to many systems. Here are some key types:

- Main Bearing Caps: It is installed at the bottom of an engine block to carry the crankshaft and ensure it maintains the correct position for positioning the main bearings. These are generally made from cast iron but might be made from steel or aluminium. The type of main bearing cap is either single-piece or multi-piece and is used to provide high strength in light of high-performance engines.

- Connecting Rod Caps: The caps link the piston to the crankshaft; this helps in transmitting the pressure created because of combustion. It is made up of either graphite cast iron micro-alloyed steel or carbon steel; its parts are bolts, nuts, and bushings. There are two types of connecting rod caps:

- Split-cap connecting rods: These are separate pieces bolted together,

- Full-cap connecting rod caps: They cover the entire bearing.

- Camshaft Bearing Caps: These caps regulate the flow of fuel and exhaust gases in an engine. There can be up to seven bearings per camshaft, depending on design. Two major types of camshafts are:

- Flat tappet camshaft

- Roller camshaft

Our Commitment

AKP Ferrocast is committed to providing high-quality bearing cap iron casting. Our product lines incorporate innovations as well as precision in manufacturing in the quest to satisfy multiple industries. With high-tech casting technology and superior quality control measures, our cast iron bearing caps products ensure excellent dimensional accuracy, durability, and reliability in application.

Our Production Process

The manufacturing of bearing caps comprises several significant steps to guarantee accurate precision and operation:

- Material Selection: It starts off with selecting the right type of cast iron that should suit the intended application. It can be any of the two, either gray iron or ductile iron.

- Mould Preparation: Pattern-making is undertaken to provide the exact shape of the mould. They help the end product to have the exact dimensions and structure required.

- Melting and Pouring: The selected metal is melted in a furnace, and then it is cast or poured into the prepared mould.

- Cooling and Solidification: The mould is allowed to cool down, whereby the metal solidifies and maintains the bearing cap shape.

- Machining and Finishing: The casting will go through machining to produce the required surface finish and exact dimensions. In this step, it is treated to improve corrosion resistance.

- Quality Control: Each bearing cap is put under strict tests to make sure that all bearing caps meet industry benchmarks in terms of strength, durability, and accuracy.

Discover Our Bearing Caps Iron Casting Solutions – Elevate Your Manufacturing Process with AKP Ferrocast's Precision Parts.

Our Expertise

The result of decades of casting experience means we have mastered producing high-quality crankshaft bearing caps, bearing caps engine components, and other essential parts. We deliver our expertise within a variety of industries – from automotive, construction, and industrial machinery, to name a few- and ensure reliable solutions contribute to the smooth operation and extended life of a wide variety of mechanical systems.

Why choose AKP Ferrocast for Bearing Cap Casting?

- Unmatched Quality: We use the finest materials and advanced casting techniques for the production of bearing caps that strictly adhere to international standards.

- Precision Engineering: We manufacture all products with careful attention to detail and precision in dimensional accuracy and durability, thus ensuring high-stress capability in harsh environments.

- Customisation: We provide custom solutions to support unique specifications and requirements for special OEM applications.

- We offer custom solutions for OEMs, catering to unique specifications and requirements for specialised applications.

- Global Supply Network: As a leading cast iron-bearing cap supplier, we have an extensive distribution network that enables us to deliver our products to any part of the world.

Comprehensive Testing: Each bearing cap assembly is put through rigorous testing that covers every aspect of its strength, durability, and performance to meet all industry standards.

Conclusion

The right bearing cap casting manufacturers can truly make a difference in how your equipment performs and lasts. AKP Ferrocast is proud to offer varied ductile and gray casting iron products to meet the many diverse needs of the world. Quality commitment, customisation, and global supply capabilities put us in an ideal position as a trusted producer of bearing cap casting.

AKP Ferrocast specialises in the casting of high-quality iron-bearing caps with international standards to meet the industry-specific and customised requirements of the clients.

Frequently Ask Questions

Can cast iron bearing caps be reused?

Yes. Cast iron bearing caps can be recycled if they are in good condition, without any signs of wear or cracking and with no other forms of damage. Inspection must be conducted to check for signs of fatigue or alignment issues before reusing it in an engine or machinery.

Does AKP Ferrocast provide custom cast iron bearing caps for OEMs?

AKP Ferrocast specialises in being the OEM solution provider, particularly in crankshaft caps and other specialised parts that we can even produce to your specifications, thereby ensuring compatibility and high performance.

What are the different industries for which we cast bearing caps?

We have comprehensive offerings for the following types of industries:

- Automotive (engines and transmissions)

- Industrial machinery (gearboxes, conveyor systems)

- Agricultural machinery (tractor engines, harvesting equipment)

- Construction equipment (cranes, excavators)

- Mining machinery (crushers and conveyor belts)

What type of metals can be used to cast bearing caps?

Although Gray Iron and Ductile Iron are the materials most commonly used for bearing caps iron casting, other materials like steel, aluminium, and stainless steel may also be used depending on specific applications requiring greater strength or corrosion resistance.

Request Pricing Details

Get a comprehensive quote based on your specific needs and requirements. Submit your request to receive detailed pricing, including product specifications, quantities, and delivery terms.