White Cast Iron (High Chrome)

Exporter & Solutions

At AKP Ferrocast, we specialize in manufacturing and exporting high-chrome white cast iron solutions engineered for maximum wear resistance, hardness, and long service life. We are a long-established white iron casting enterprise, serving industries with components that perform constant abrasion, friction, impact, and extreme conditions, including mining and cement plants, construction equipment and heavy vehicles, and mineral processing systems.

Our castings are produced using advanced metallurgical methods to ensure exceptional hardness, impact strength, corrosion resistance, and dimensional stability. Every component is created in a controlled foundry environment, following ASTM and EN standards, ensuring predictable performance and long operational life.

Having extensive experience in the high-chrome white iron casting service, we help our customers in the world reduce downtime, increase the life of equipment and lower the total maintenance expenses. Being a reputed white cast iron producer and exporter, the AKP Ferrocast provides reliable solutions in accordance with the environment, load requirements and wear patterns in your application.

Key Advantages of White Cast Iron (High Chrome) in Wear Applications

Performance Advantages:

- Exceptional Wear Resistance: The high chromium level makes it hard and minimizes wear on the surface, which is apt for mining, cement, and construction.

- Superior Hardness: With a hardness range of 450–650 HB, high-chrome white iron withstands continuous abrasion, impact, and high-velocity particulate flow.

- Corrosion & Chemical Resistance: Suitable for slurry systems, mineral processing, and environments exposed to moisture and corrosive media.

- Dimensional Stability: Maintains structural accuracy and performance even under elevated temperatures and long operation cycles.

- Cost Efficiency: Lower maintenance frequency and extended part life add to optimized operational costs.

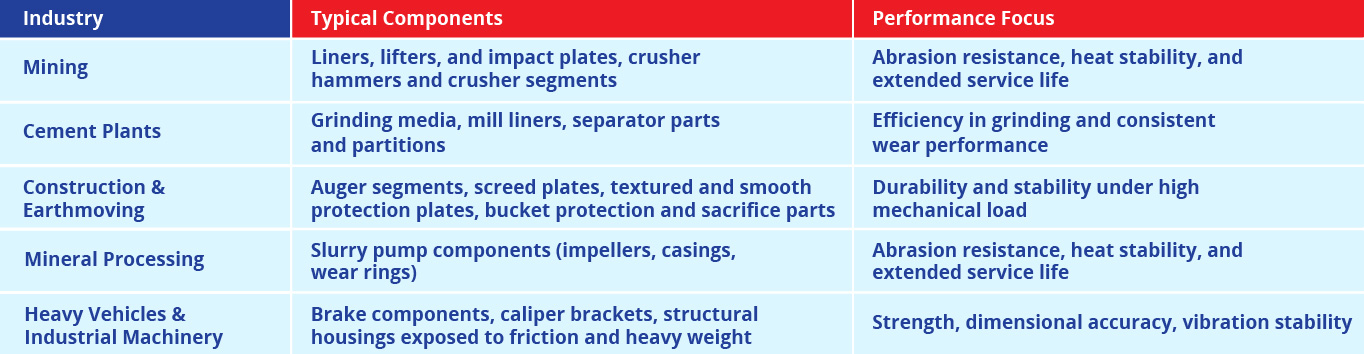

Applications of High-Chrome White Cast Iron in Heavy & Wear Systems

High-chrome white iron castings are used across industries that need long-lasting, wear-resistant components. AKP Ferrocast supplies precisely engineered castings for the following applications:

Product Families & Components in White Cast Iron

AKP Ferrocast manufactures a diversified portfolio of precision-engineered white cast iron components tailored for high-load and abrasive applications.

Our Major Product Families:

- Textured plates, smooth plates, and liners

- Auger segments and half-segments

- Brake systems and caliper brackets

- Crusher hammers and grinding balls

- Pump bodies, casings, impellers, and slurry handling components

Every component undergoes strict metallurgical, mechanical, and hardness testing to ensure durability and consistency across batches.

High-Chrome White Iron Grades & Material Properties

AKP Ferrocast produces white cast iron according to globally recognized standards, ensuring high reliability and predictable behavior under stress.

Common Grades

- ASTM A532 Class III Type A

- EN 12513 – EN-GJN-HB340

Key Material Properties

- Hardness: 450 – 650 HB

- Microstructure: Carbide-rich matrix for superior wear resistance

- Performance: Excellent under compressive stress and high-abrasion conditions

- Thermal Stability: Retains mechanical integrity at elevated temperatures

These grades are ideal for grinding, crushing, slurry transport, and high-impact industrial applications.

Discover Our White Casting Solutions – Elevate Your Manufacturing Process with AKP Ferrocast's Precision Parts.

OEM White Iron Castings for Heavy Vehicles & Industrial Systems

As a trusted OEM partner, AKP Ferrocast develops and supplies customized white iron castings built to meet precise engineering requirements.

OEM Capabilities

- Prototype development

- Small-batch production

- Large-scale manufacturing

- Custom alloy design based on wear behavior

- Dimensional optimization for specific machinery

Our team evaluates operating environment, wear zones, impact patterns, and load conditions to determine the best high-chrome grade and casting configuration for your application.

Precision Machining & Finishing for White Iron Castings

High-chrome white iron requires specialized machining due to its hardness and carbide content. We provide in-house machining that makes sure every part meets tight tolerances and installation-ready accuracy.

Machining & Finishing Capabilities

- CNC turning and milling

- Surface grinding and polishing

- Dimensional verification & fit-testing

- Coating and assembly support

Our machining processes protect the carbide-rich structure, delivering the precision needed for heavy equipment, pumps, industrial machinery, and braking systems.

Why Choose AKP Ferrocast for White Cast Iron (High Chrome) Solutions

Global buyers across mining, construction, cement, and heavy equipment industries rely on AKP Ferrocast for:

- Decades of foundry & metallurgical expertise

- Advanced high-chrome casting solutions

- Customized material compositions for specific wear conditions

- Fast lead times and consistent deliveries

- Strict quality control aligned with ASTM, EN & ISO standards

- Strong OEM support and global export capability

We deliver castings that integrate seamlessly into complex machinery and make sure longer service life, lower downtime, and reliable operational performance.

Conclusion

High-chrome white cast iron remains one of the most reliable materials for systems subjected to extreme wear, abrasion, and impact. With its hardness, stability, and predictable behavior, it is essential for rugged, heavy-duty industrial operations.

AKP Ferrocast provides world-class castings engineered for demanding environments—ensuring longevity, consistency, and superior performance across mining, cement, construction, industrial machinery, and heavy vehicles.

Frequently Ask Questions

Do you provide technical support for selecting the right White Iron Castings alloy?

Yes. The engineering division assists in identifying the most appropriate grade depending on wear conditions, impact load and service conditions.

What is the typical lead time for White Iron Castings orders?

Lead times generally range from 4–8 weeks, depending on part complexity and production volume.

Can you supply both prototypes and full production runs?

Absolutely. We support prototype development, limited batch production, and high-volume manufacturing.

Are machining or finishing services included?

Yes. Castings can be supplied as-cast or fully machined, depending on your requirement.

What sizes and shapes can you produce?

We manufacture castings ranging from 10 kg to 400 kg, including complex geometries and customized profiles.

What quality standards do you follow?

Our foundry operates under ASTM, EN, and ISO-approved processes, ensuring every component meets global performance and reliability benchmarks.